Screws have long been used in the human body as anchors for sutures. But screws can come loose, especially in individuals of advancing age.

That’s why MedShape sought to find a solution using shape-memory polymer (SMP). In simplest terms, a polymer is a material composed of many repeating units. Shape-memory polymer starts in an initial shape, transforms into a different shape via a trigger, and then returns to its initial shape.

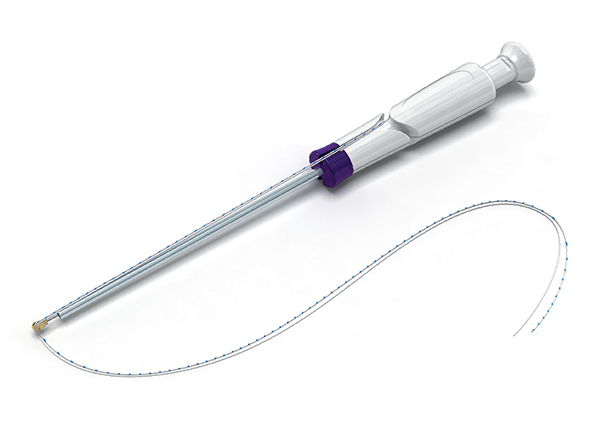

Backed by Phase I and Phase II Small Business Innovative Research (SBIR) grants from the NIH National Institute of Arthritis and Musculoskeletal and Skin Diseases, MedShape took an undeveloped technology and successfully transformed it into Morphix®, a suture anchor made of SMP and designed to reattach soft tissue to bone.

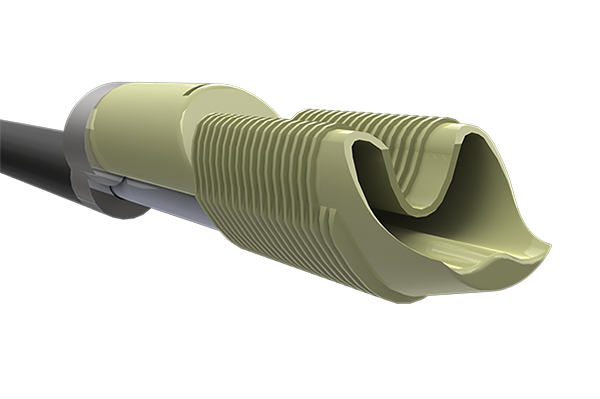

Unlike a screw, Morphix does not rely upon threads for adhesion. Instead, it operates the way a ship in a bottle works. Once the ship is in the bottle, the bottle’s neck is too small for the ship to slip through. Similarly, surgeons insert the Morphix into a tunnel drilled into bone. Through its shape-changing design, Morphix deploys wings that expand, preventing it from pulling out of the tunnel. Surgeons then use attached sutures to affix the bone to soft tissue.

For patients, the Morphix device is less invasive than a traditional titanium screw-anchored suture, and for surgeons, it is easier to insert. More importantly, in both healthy and aging bones, the anchor is rock solid.

Thank you, NIH, for the grants. They have been very helpful to us, particularly in the very early days when the technology was unproven.

Kurt Jacobus, Ph.D., president and CEO of MedShape, credits NIH Small Business Innovation Research (SBIR) grants from the National Institute of Arthritis and Musculoskeletal and Skin Diseases with helping the company overcome initial challenges in developing SMPs for suture anchors. The first SMP MedShape developed had never been used in the human body. Thus, a large part of the development process was assuring biocompatibility through a series of increasingly stringent checks, beginning with studies at the laboratory bench and later extensive animal tests.

Kurt Jacobus, Ph.D., president and CEO of MedShape, credits NIH Small Business Innovation Research (SBIR) grants from the National Institute of Arthritis and Musculoskeletal and Skin Diseases with helping the company overcome initial challenges in developing SMPs for suture anchors. The first SMP MedShape developed had never been used in the human body. Thus, a large part of the development process was assuring biocompatibility through a series of increasingly stringent checks, beginning with studies at the laboratory bench and later extensive animal tests.

The SBIR grants also contributed to MedShape’s successful development of other SMP-based products— Eclipse™, an anchor that connects soft tissue to bone, and ExoShape®, sold to ConMed Corporation, used in knee reconstruction. Jacobus acknowledged that the core understanding of the technology platform, which enabled this additional product development, resulted directly from the NIH SBIR Phase I and II grants.

The company is clearly on an upward trajectory, and Jacobus does not take this for granted. He recognizes the value added, early on, from NIH’s financial assistance. “Thank you, NIH, for the grants. They have been very helpful to us, particularly in the very early days when the technology was unproven.”